Produktionsmechaniker/-in Textil

Berufschancen heute

Textile Production Mechanic (Gesamter Film)

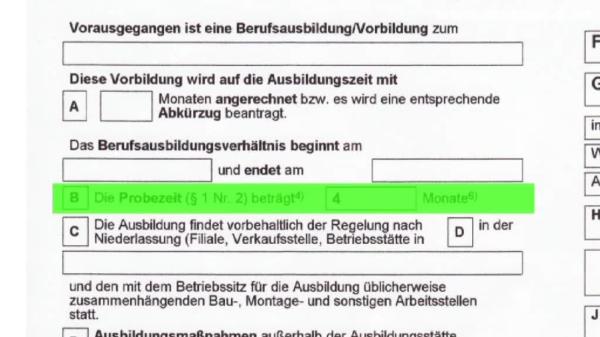

1. The Search N: “Hello Jürgen.” J: “Hello Mr. Nüsslein.” N: “I’m glad to see you again around here. We met in school the last time, and talked about this and that. How are you doing in school?” J: “Everything is going well, thanks.” N: “Good to hear – How is your social studies class?” J: “Social studies…as far as grades are concerned: C.” N: ”Oh…and what are your strengths?” J: “I’m good in math, physics, and chemistry.” N “Have you ever given a thought as to what you do with your education?” J: “Yes. I thought the field of technology - mechanics would be an option.” N: “What kind of hobbies do you have?” J: “At the moment I’m helping my dad tune up a Golf, and also I’m doing some work on my motorcycle.” Due to the fact that starting training in the field of mechanics has become totally obsolete, Jürgen ventures out to see a career counsellor for alternatives. Interests in technical procedures, sympathy for mechanics and the ability to work with engines are perfect reasons for a job in the textile industry, which is desperately seeking new employees. The career counsellor introduces the job of a production mechanic specialized in textile to Jürgen: “Your job is to set and operate the production line and perform maintenance work on it. Additionally, you are to manage the production flow and to execute quality checks.” N: “Does that sound very tempting to you?” J: “Yes, of course!” N: “Fine. I would like to give you a flyer with some information about the job “production mechanic” on it.” J: “Thank you.” N: You’re welcome – take a look at it.” J: “Ok, I will.” N: “If we get to an agreement, we will take actions to get you an internship. The advantage of internships is that you get to know the company you work for, you get first-hand experience about the different tasks that are to be performed, and you get to know the workers, so subsequently you are in the position to pass your own judgement based upon the impressions you get. If you are still interested after the internship and positive about the job, we can start making arrangements and look for a training post. Would that work with you?” J: “Certainly.” N: “Great. Then that’ll do it for today and let’s see what happens.” 2. First Steps 2.1 The Business Jürgen applies to the training supervisor of “Brennet AG” for an internship. First of all, he is informed about the goods the company produce mainly consisting of fabrics for shirts and blouses, for work clothes and bed-linen. The production from yarn to textures provides the chance to develop premium-quality products. Now both are in the weaving department. Hundreds of weaving machines are put up here, all of them waiting to be set, monitored, maintained, and repaired. Those tasks are performed by a production mechanic specialized in weaving systems. Note that a computer is the necessary component in the handling of those machines. Once the machines are set up, they run almost automatically, but only almost, because every now and then a thread breaks. Thank God, that the training supervisor is present. So he can demonstrate how to solve a problem like this. In an instant the machine is running again. At last we take a look at the final inspection department. The sharp eyes and sensitive hands of our employees don’t miss a single flaw. 2.2 Requirements Every year prospects for the job of a production mechanic are trained in the weaving, spinning and equipment department. The basic requirement is a extended elementary school diploma. In the beginning we introduce the trainees to the materials, we use. From early on they get to know the machinery we utilize to produce our fabrics. Our experienced colleagues and instructors introduce them step by step to their tasks. Even during training an independent work ethic is expected of our trainees, whereas the results are checked continuously. Their alertness and endurance are intensely challenged, because they are controlling a couple of machines simultaneously. While setting up and maintaining the machines varying tasks have to be completed. A high deal of concentration is due and working exactly in accordance with security regulation is absolutely necessary. Altogether it is a very demanding job. We pay close attention to aspects like technical affiliation, an independent attitude towards work, and reliance. 2.3 The Job Production mechanics set our fully or partly automated production machinery located in the spinning department. They operate, monitor, maintain and repair the machines. However, most of the times they are busy with setting the machines, because for each new assignment the machines have to be changed over and adjusted. Process parameters such as operating speed, tractive force, and a thread’s tension are determined and set via the control system. The data for the pattern of a fabric are retrieved from a memory chip. In order to determine whether a program is running correctly, production mechanics do test runs. In the case there is a deviation in results to the specifications, re-adjustment of the system has to be undergone. If a machine should shut down, one of our mechanics is going to be on the spot immediately. Often times either the chain or a thread is broken, which is fixed in a second. Despite being under pressure our mechanics stay calm and focussed. We have to give credit to our mechanics for achieving a smoothly functioning production line. Thanks to them, we have been able to provide our customers constantly with flawless quality. In addition to it they are also responsible for a trouble-free production – whether it be during late shift, night shift, or on the weekends. 2.4 Rights and obligations There are some points mentioned in the contract that have to be taken into consideration. First of all, there are the names of the contract partners. The instructor has to write his name in here and you have to place your name here. The next step is to define the job: production mechanic specialized in textiles. Training lasts for 3 years and you are on probation for 4 months. Your wages, daily working hours and vacation depend on the actual collective wage agreement, administered by the state. And last your signature. Your responsibilities are described in fine print. During the course of training you have to take on general working techniques and gain proper knowledge of their functionality in order to meet the requirements to graduate, meaning you have to …attend school on a regular basis …use tools in the proper way …follow instructions If there is anything written in the contract you don’t understand, feel free to ask me prior to signing. 3. Vocational Training 3.1 Working independently During the first couple of days of training the trainees are introduced to all the departments, in which they later gain their practical experience. You already get an impression of the versatility of the job and the high technological standards of our machines. Very soon you will be working hard. The trainees will then cut off of a piece of fabric for their actual exam. Only when it is working properly, the machine can be handed over to the operator. The toughest part is to place the fabrics accurately onto the rolls. As of now, trainees are still lacking practice. But as time goes on a routine establishes. The foreman predicts, that if both of the trainees continue ambitiously, they won’t have to worry about their future. In the cutting department the spools of yarn have to be placed onto the gate precisely, in accordance with the order. Over and over again the job must be reviewed by the trainees themselves with respect to the education they gain in school. The smallest mistake results in failure and the wrong pattern is going to be woven. 3.2 Every day training routine The first thing you learn is to never walk around the machine hall without ear protection. The machines run 24/7. In order for them not to shut down due to external hazards, they have to be cleared off fiber dust regularly and bearings as well as the transmission have to be lubricated. During the first half of training, our trainees get to know various procedures to supply the machines with new materials. They learn step by step how the weaving mechanism works and to what aspects they have to pay attention to. Daniel is already responsible for the quality of the material and secures a trouble-free production process. In case of a machine shutting down, he instantly reports to the supervisor. The woven fabric has to be checked and compared with the sample continuously. Daniel has to be highly focussed on the status of all the machines making sure that they are set accordingly and that plenty of yarn in the right color is available. In order to be in the position to set and adjust the machines, our trainees have to learn first, what to take into account concerning woven fabrics. They learn about the important facts while performing quality checks at the light table. Here the textile is compared to the given sample and simply checked by eye. Using a thread counter Daniel checks the yarn spacing (density). In case the fabric deviates from the sample, he calls upon the supervisor. He, then, would have to find the error. Usually everything functions properly though – the status is recorded on a form-sheet. Finally, both trainees get to prove that they know how to use the wrench as they get to work on one of the weaving machines. Their supervisor demonstrates every step, so that they are perfectly prepared to take the exam. 3.3 Advanced industrial training GATEX stands for community training center specializing in fabrics. The company was founded by 7 entrepreneurs 29 years ago. Many factories have undergone a specialization process, so that they aren’t in the position anymore to offer an extensive training program. GATEX takes on those cases. Due to our broad educating program, our graduates are equipped to work in any field of the textile industry: in the spinning, weaving, and knitting industry. Even though products and machinery differ, their tasks are usually the same. Our instructors are experienced engineers and technicians passing on their knowledge about the technology to our students. Our training is a reasonable addition to the actual training program of the companies, where most of the students are exposed to only a part of what the job is about. We teach them to document the chain of events while preparing the machines. This way the individual thinking and working process are both promoted. This is the path the string takes. All the way in the back they start coming in and are distorted once reaching the stretching unit. We achieve a distortion of six times of the actual length along with a doubling of six times. Afterwards the string is put into a can and brought to the spindle. The transmission of the spinning machine has to be exchanged in order to be able to produce the demanded thread size, referring to the thread number. There are exact instructions and regulation for adjustments. Once the machine has been changed over to the new standards and runs, the spinning of the yarn is ignited. A lot of soft skills and patience is essential here. Trainee: “The problem with preparing the machine is that if I do it slowly, it winds up by itself all the time. Consequently I would have to do it a little faster.” At the factory this process is automated. In training we have to do it by hand. 4. School Education 4.1 Every-day routine at school Classes are arranged in a block schedule pattern, with each block lasting a couple of weeks. The set up of classes aims to promote an independent und responsible thinking, decision making and planning process by our students. Teacher: “Now we don’t teach the theoretical part concerning the field of textiles, in independent classes, but invented a system of study blocks. The advantage is that theoretical classes such as technology, mathematics, and drafting don’t stand alone and are taught partially anonymously and without any relation to each other. Those classes are now project-oriented incorporating classes of one study block. “ There are 14 different study blocks: During the 1 year of training: Adjusting Production processes to textile articles Using fiber materials Production of line-like textile images Production of textile areas Monitoring production processes During the 2nd year of training: Copying of textile products Using textile materials in preparation processes Treating of substances for machine elements Maintaining the machinery Refining of textiles according to customer’s wishes During the 3rd year of training: Preparing the machinery Maintaining the machinery Using modified textiles Realization of customers’ orders Perform quality securing tasks Teacher: “Who knows what these 12,6% mean and can put into words?” Student: “The fabric is 12,6% shorter than the length of the thread.” 4.2 Exams At the end of the 2nd year of training our student have to take their midterms, so we are able to determine the training status of each student. Finals consist of a practical and a theoretical exam. During the practical test our trainees have to prepare, execute a task and perform follow up work afterwards. The theoretical part comprises the following: Product Engineering Systems Engineering Social Studies In case of failure, exams may be retaken twice. These young and ambitious apprentices will get a very prestigious qualification. Soon they will be given great responsibilities with great prospects. J: “That was very interesting. The job seems to offer many fields of action. I could see myself doing that type of job in the future.”